Sponsored By

Latest

plastic trash on beach

Sustainability

Coca-Cola Is Not the ‘World’s Biggest Known Plastic Polluter’

Coca-Cola Is Not the ‘World’s Biggest Known Plastic Polluter’

Nor is Pepsi. The methodology behind a new study is maddeningly stupid.

NPE News

Thermoformer Claims Highest Throughput per Square Foot

At NPE2024, WM Thermoforming Machines will preview a new thermoforming concept launching later this year.

Apr 22, 2024

|

2 Min Read

PackagingR&B Plastics Highlights Electric Extrusion Blow Molding Shuttle at NPE

Apr 22, 2024

|

2 Min Read

Injection MoldingNew Injection Molding Nozzles Improve Gate Quality, Facilitate Maintenance

Apr 16, 2024

|

1 Min Read

Hot Right Now

Sign up for the PlasticsToday NewsFeed newsletter.

Dispatches from the War on Plastics

Coca-Cola Is Not the ‘World’s Biggest Known Plastic Polluter’

Nor is Pepsi. The methodology behind a new study is maddeningly stupid.

Apr 25, 2024

|

3 Min Read

Mechanical RecyclingPlanet vs. Plastics: Not All Plastic Problems Are the Same

Apr 22, 2024

|

6 Min Read

Legislation & RegulationsWhat to Expect From Global Plastics Treaty Talks This Month

Apr 14, 2024

|

4 Min Read

Legislation & RegulationsNew EPA Rule Deeply Concerning for Chemicals Industry

Apr 9, 2024

|

3 Min Read

Must Read

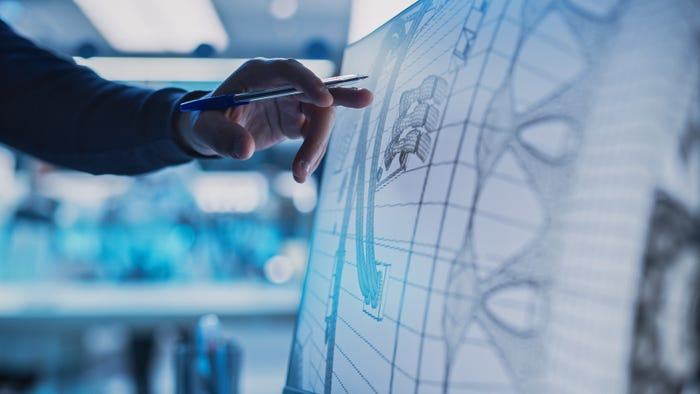

Plastic Part Design: Selecting Appropriate Screw Fasteners

In the first of this two-part series, design engineer Michael Paloian details key considerations in specifying screw fasteners for plastics, including the type of screw, size, length, and material.

Slideshows

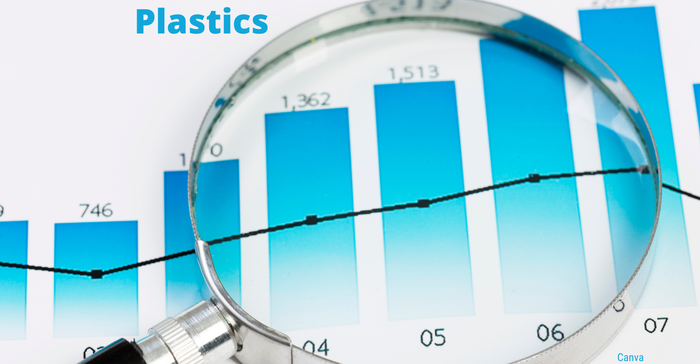

Plastics by the Numbers

Plastics market reports for thermoform packaging, thin-wall packaging, polyethylene furanoate (PEF), functional films, PCR plastics, and more are featured in this slideshow.

Apr 23, 2024

|

11 Slides

Popular

Discover the latest thinking in injection molding, 3D printing, and new materials, and meet professionals at the heart of design and manufacturing at the Southeast’s largest plastics and polymers trade show. Plastec South is part of IME South, a six-in-one expo offering the latest insights & solutions spanning medtech, packaging, automation, plastics, design, and processing.

Register NowRecent